Technical Assessment

Prior to commencing the production phase, our engineering team conducts a thorough technical evaluation of your part's design. This evaluation includes material selection, surface finish evaluation, structural considerations, and a comprehensive review of both 3D and 2D drawings.

On-site Inspection

From the moment your order is in production, it enters a meticulous procedure that prioritizes quality at every step. Our team ensures that each element, from material selection to machining and finishing, is inspected and met with precision.

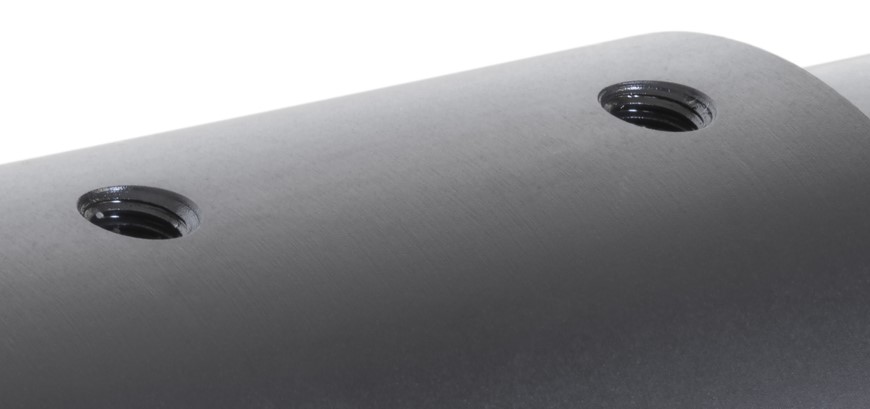

Quality Control

We provide a detailed inspection report validating the parts' production quantity, dimensions, and appearance. During this stage, we meticulously assess the order's color, texture, and other subtle physical attributes to ensure each aspect meets the highest standards.

Packaging

To address logistics' unpredictability, we've established a thorough packaging process to protect your parts in transit. Our multi-layer system, varying by destination, includes wrapping paper, EPE, foam, and box packaging, ensuring defect-free arrival of your products.